emissions from the company

Longevity in the purchase of internal operating and office equipment

Durability and reparability are the focus at allsafe - also when purchasing our office and business equipment. Our office chairs have been in use for over 20 years and are regularly repaired and maintained. In our offices, we rely on timeless, hard-wearing industrial parquet flooring that will last for decades. Even walls are not simply disposed of, but carefully dismantled, stored and reused as required. We even build some of our furniture ourselves. For our terrace in Fürstenwalde, we welded a table ourselves and sourced wood for the top from a neighboring wood pallet construction company.

In production, too, we keep what we have instead of buying new. That's why we comprehensively overhauled two large systems in 2021 and 2023 instead of replacing them with new machines. This allows us to extend the useful life of our equipment and save valuable resources.

Resource requirements and energy consumption

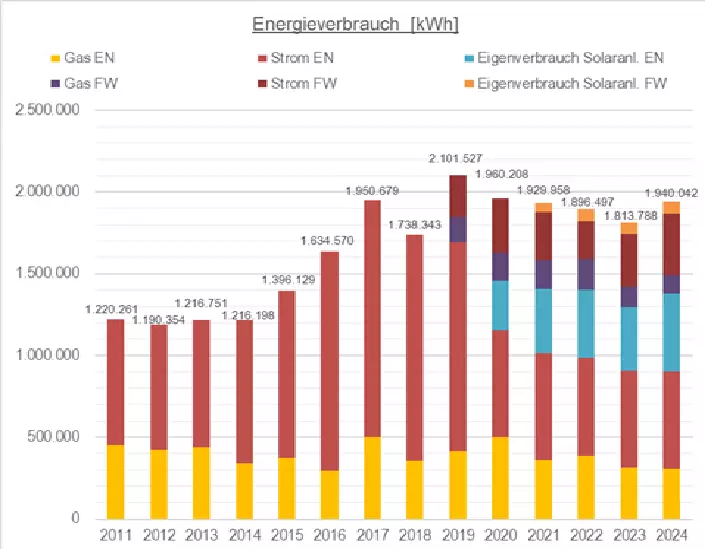

Heating is provided by gas. In Engen, consumption in 2024 was 307,632 kWh. In Fürstenwalde, we consumed 111,683 kWh in 2024.

Water consumption and waste management

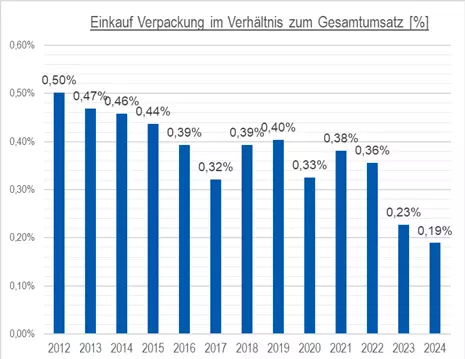

Our water consumption is low for both sites, as no water is required to manufacture our products. At the same time, we focus on the sustainable recycling of rainwater: the water from the roof areas is collected via our biotopes and returned to the environment in a natural way. When it comes to waste management, we pursue a clear strategy of reuse and reduction. By standardizing our packaging, we are increasingly relying on cardboard and have largely banned plastic from our shipping. We continue to use incoming packaging and have introduced reusable packaging such as wooden crates or mesh boxes with numerous partners. In 2024, we were already able to transfer 25% of our purchases to such sustainable packaging concepts. Our "Packaging optimization" project has achieved a great deal since 2021: we are working with suppliers on return agreements for wooden pallets and cardboard boxes and are developing packaging reduction solutions with our customers. One example: cardboard inserts from beams can be collected and returned to us together with the racks. This enables us to make efficient use of packaging and reduce the need for new materials. We have also been able to significantly reduce the amount of waste materials. For example, we were able to reduce the amount of waste paper from 40 tons in 2023 to 30 tons in 2024. The situation is similar for waste wood and commercial waste: Waste wood (EN+FW): 56.24 tons (2024) / 67 tons (2023) Commercial waste (EN+FW): 20.68 tons (2024) / 25.6 tons (2023) 32 tons.The effects are measurable: our consumption of packaging material in relation to total sales has fallen continuously in recent years.

Waste avoidance and responsible handling of hazardous substances

Mobility - Efficiently on the move for our customers

Commuting - resource-saving and flexible on the move

Do you have any questions for us?

Please feel free to contact us. We are here for you personally and will be happy to help you.