Material cycle

As part of our Scope 3 assessment at product level, we consider the entire material cycle: from material procurement and processing through to the transportation and removal of raw materials, finished products and industrial waste, as well as the recycling of products. In doing so, we analyze the environmental impact of purchased materials, their route to us and the finished products to our customers, as well as the handling of industrial waste and recycled materials. Our aim is to create transparency about indirect emissions and identify potential for reduction.

Material procurement

We are specialists in load securing and focus on sustainable material procurement. Our products are made of aluminum, steel, rubber and plastic - materials that we select with a view to efficiency, environmental compatibility and resource conservation.

Aluminum is our preferred primary product as it offers an optimal balance between stability and weight. Due to its low weight, it enables energy savings during transportation and contributes to the sustainability of our products. Right from the development phase, we pay attention to the material efficiency, reparability and recyclability of our raw materials in order to maximize the life cycle of our products.

We minimize our ecological footprint through a conscious selection of primary materials, optimized manufacturing methods and environmentally friendly production techniques.

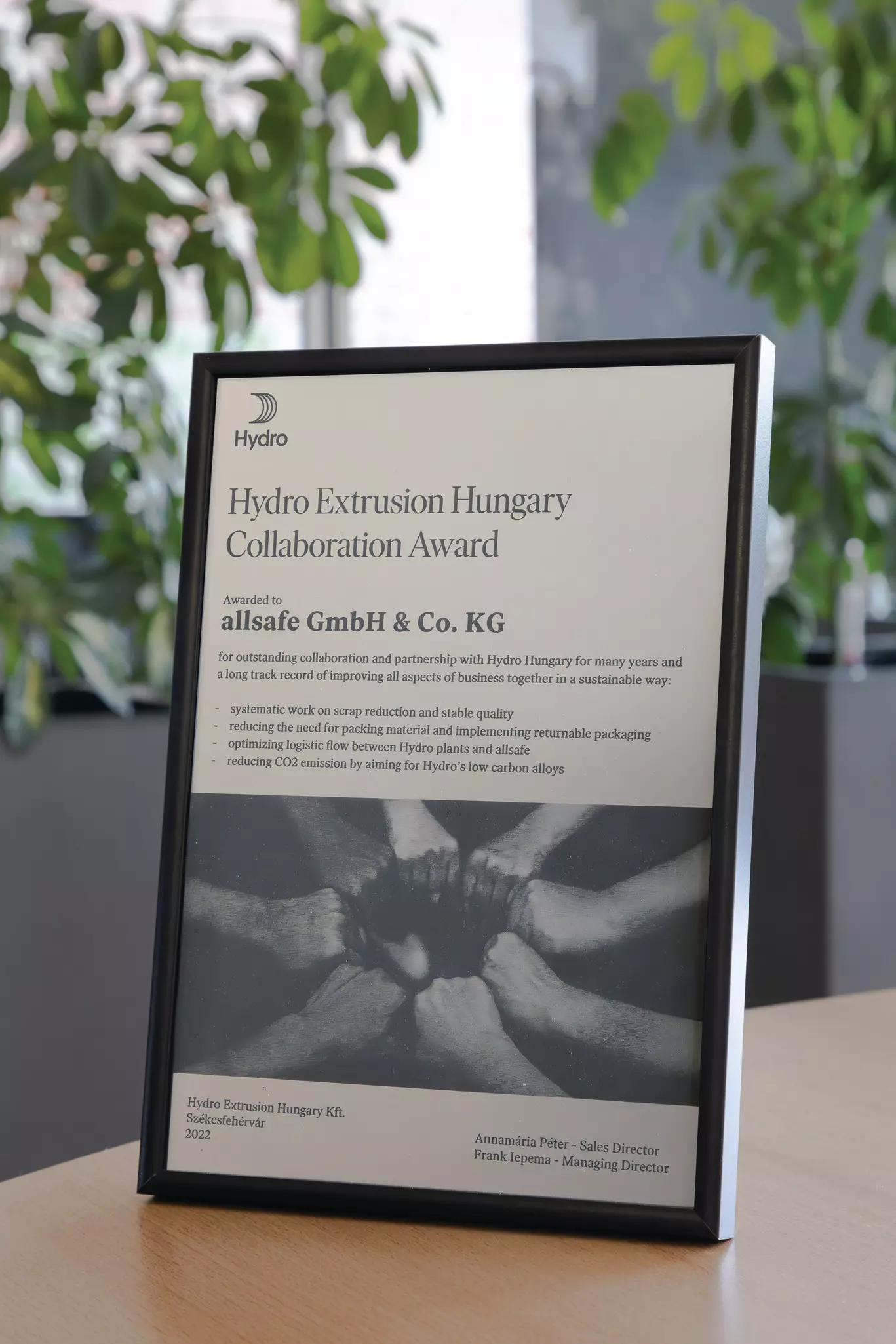

Climate partnership with Hydro

Sustainability starts with the right partners. That is why we are particularly proud to have been recognized as a climate partner by our main aluminium supplier Hydro.

An important milestone was reached in 2022: for the first time, we were able to source a large proportion of CO₂-reduced aluminum from Hydro. By using recycled aluminum and aluminum produced with renewable energies, we are making an active contribution to reducing our carbon footprint - the positive effect is clearly visible in the carbon footprint.

This partnership is an important step for us towards a more sustainable value chain. Together, we are focusing on healthy business practices and the use of resource-saving materials.

Supplier selection - ISO 14001 certification

We rely on the highest quality and environmental standards to ensure a responsible value chain. All of our suppliers are certified in accordance with ISO 9001, and around 76% also meet the requirements of the environmental management standard ISO 14001 (in relation to our purchasing volume).

In order to further reduce delivery times and distances, we have opened a second production facility in north-eastern Germany. In addition to our previous location in Engen (Baden-Württemberg), allsafe has also been producing in Fürstenwalde (Brandenburg) since February 2019. With this conscious decision to open another site in Germany - especially in a structurally weaker region - we are not only strengthening the regional economy, but also reducing transport emissions and optimizing our logistics processes.

In addition to ecological criteria, we attach great importance to fair prices, reliable delivery conditions and long-term partnerships. Fairness is one of our four core corporate values - which is why we support our suppliers when they face challenges and rely on trusting cooperation. Our goal: sustainable business relationships and an environmentally friendly supply chain.

We source our raw materials primarily from Germany and Europe - we have largely eliminated imports from the Far East. Together with our development team, we are continuously working on solutions to make our material procurement even more regional. For us, choosing European suppliers not only means shorter transportation routes, but also higher quality, environmental and safety standards.

Do you have any questions?

Feel free to give us a call, we'll be happy to help!