Sustainability communication

The circular economy, repairing, exchanging and reusing are part of our everyday practice - and we share this actively and transparently. We make our measures, internal and external campaigns, successes and experiences visible in a variety of ways. Since 2022, an energy display in the entrance area of our site in Engen has shown our electricity consumption for the previous week, the last 12 months and the last few years - making our energy consumption transparent for our employees and visitors. With our annual sustainability report and annual carbon footprint, we provide clarity and record all our internal and external actions for sustainable work, write about our progress and visualize our carbon footprint in Scope 1 to 3.

all:change wins DNP 2024

Our repair service all:change won the German Sustainability Award in the products category in 2024. We regularly report on all:change - whether in the trade press, social media or podcasts - because it is exemplary for circular business models. We also set regional accents: With the join-in day, we want to raise awareness of the circular economy, encourage, inspire and offer a space to experiment and try things out and build a network. We were awarded the Constance district climate protection prize for this concept. We regularly publish content on our social media channels (Facebook, LinkedIn, Instagram, YouTube) to spread the word about sustainability. On Instagram in particular, we regularly take our community behind the scenes and provide insights into our projects and successes relating to the circular economy.At allsafe, we consciously communicate sustainability in order to raise awareness, provide information and encourage healthy business practices.

Participation day on the circular economy - experiencing and shaping sustainability together

As a company, we bear social responsibility - and we want to make active use of this. With our hands-on day on the circular economy, we not only create space for exchange and inspiration, but also make sustainability tangible. Our aim is to communicate climate protection with ease and encourage concrete changes in everyday life. This interactive event focuses on less consumption and more circular economy. We offer a creative space to try things out and experiment, showing how even small changes can have a big impact on the environment. This makes the circular economy tangible - for our employees, fellow citizens and companies who also want to take responsibility.But our commitment goes beyond the hands-on day: we want to inspire others and establish this event format as a multiplier for sustainable action. Whether through associations, sustainability-oriented companies or city councils - the concept can easily be transferred to other regions.The next generation is also particularly important to us. With an attractive children's program, we create playful starting points to promote an awareness of environmental protection and sustainable behavior at an early age - with fun, enjoyment and community. The hands-on day on the circular economy: a day that shows that everyone can make a contribution - and that sustainability is really fun.

allsafe.

Your success with a visible attitude

Energy audit

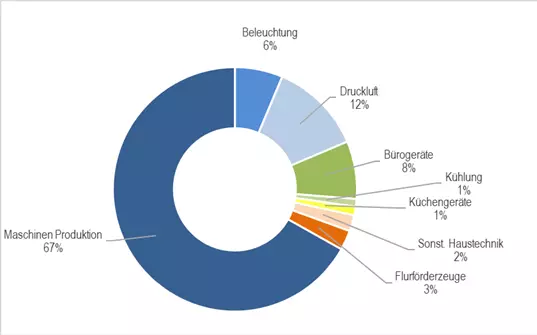

In 2018, our first energy audit in accordance with DIN 16247 took place at our site in Engen. TÜV Süd confirmed that we achieve a high level of energy efficiency. All measures were examined and optimizations have been made. Our 2nd audit in 2022 also included our 2nd production facility in Fürstenwalde. In addition to various key energy figures, the auditors also draw up an energy requirement certificate for the Engen and Fürstenwalde sites. This is valid for 5 years and will be renewed at the next audit. Our production machines are responsible for the greatest energy consumption. We currently see little potential for savings here. In the area of lighting, we were able to significantly reduce electricity consumption by switching to LED. Our production halls have been equipped with LED lighting that can be flexibly controlled and dimmed so that the different working times and lighting requirements of individual production areas can be specifically addressed through line-oriented segmentation.

Do you have any questions for us?

Please feel free to contact us. We are here for you personally and will be happy to help you.